Floor finished

It took a little longer than expected but finally the oak floorboards are down ! I'm really happy with the result and very pleased with the look of the boards.

It took a little longer than expected but finally the oak floorboards are down ! I'm really happy with the result and very pleased with the look of the boards.

The photo only shows progress half-way across the floor, but you would get the general idea.

After my previous experience of laying pine floorboards I was much more careful about getting every row straight and flush before proceeding with the next row. Every plank was checked for splinters, or muck in the groove and all the tongues swept of dust etc. before the next row was placed. Occasionally a board did not quite seat correctly and needed clamping to pull everything together. This time I used some old sash cramps in reverse to squeeze the boards against each other to ensure I always had a straight edge to work against.  Fortunately there were only a couple of instances where I needed the cramps but it does slow up the process. Compared to the pine planks before these were much much better.

Fortunately there were only a couple of instances where I needed the cramps but it does slow up the process. Compared to the pine planks before these were much much better.

One thing that made progress quite slow was the nailing. I did do some research and found that there is a special floorboard nailing gun that fires the nail into the tongue at 45 degrees and punches it home. The perfect tool for the job. However all the hire shops I visited with picture of tool in hand either gave me a shrug of the shoulders or said, 'Yeh, seen one of those on tele, but we just do it by hand'. I did find a local shop that could order and sell me one, but at 500+ euros it seemed a little expensive for a one off job.

Impatience and the cheapskate in me decided to do it by hand. How difficult could it be to bang in a few nails :-) Well it turned out that getting the right nails was a challenge in itself.  I wanted lost head nails with serrations (barbs) down the shaft because I was nailing through hardwood into softwood and wanted the extra grip to hold the planks down and stop and squeaking and movement in the future. Again, trips to several DIY stores and builders merchants turned up nothing. Even the builders merchant thick nail and screw catalogue had nothing suitable to order. In the end I settled on a stainless steel nail with serrations, but a rounded head. Therefore every nail had to countersunk, and banged home (with some difficulty) with a punch. My hammering skills have certainly improved over the last few days, however I did catch the edge of some boards with the hammer head, so a few little dents here and there. Oak is tough, but not that tough. Any ideas on how to remove the dents on the edges of the planks would be appreciated.

I wanted lost head nails with serrations (barbs) down the shaft because I was nailing through hardwood into softwood and wanted the extra grip to hold the planks down and stop and squeaking and movement in the future. Again, trips to several DIY stores and builders merchants turned up nothing. Even the builders merchant thick nail and screw catalogue had nothing suitable to order. In the end I settled on a stainless steel nail with serrations, but a rounded head. Therefore every nail had to countersunk, and banged home (with some difficulty) with a punch. My hammering skills have certainly improved over the last few days, however I did catch the edge of some boards with the hammer head, so a few little dents here and there. Oak is tough, but not that tough. Any ideas on how to remove the dents on the edges of the planks would be appreciated.

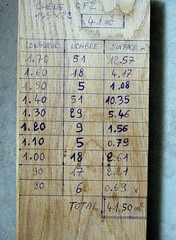

BTW - If you are wondering about my crazy multi-coloured floor laying plan, the inventory of planks supplied by the sawmill might explain things.

BTW - If you are wondering about my crazy multi-coloured floor laying plan, the inventory of planks supplied by the sawmill might explain things.

So after four days, 1000 nails, a sore back and forty square meters, we have a floor. No more mud.

| 9:06:57 PM